| Feature | Value | Icon |

|---|---|---|

| Film Foggy | 13 ± 2 | |

| Transparency | 83 ± 2 | |

| Ink Absorption | Balanced Hold | |

| Film Grammage | 174 ± 2 g/m² | |

| Base Grammage | 140 ± 2 g/m² | |

| Ink Compatibility | Dye / Pigment ink | |

Still have questions? Here are some of the most common inquiries we get from buyers and distributors.

A: Our inkjet film is designed for inkjet printers, especially Epson models. It supports both dye and pigment inks. It is not recommended for thermal inkjet printers such as certain HP or Canon models.

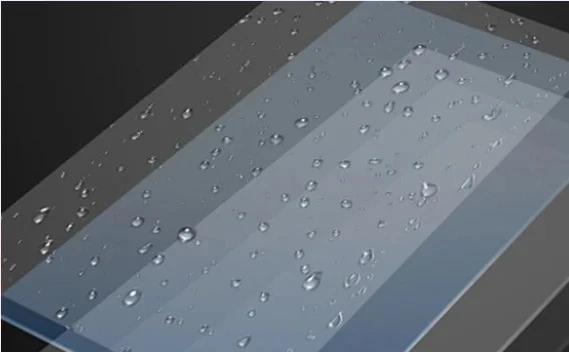

A: Optical Density (OD) shows how much light the film blocks. It affects the sharpness and accuracy of the print. Our waterproof inkjet transparency film has an OD over 3.0. This gives solid blacks, clear edges, and less light bleed for better screen printing results.

A: Waterproof film resists smudging and keeps prints sharp, even with dye based inks or heavy ink loads. Non-waterproof film can blur in humid conditions or when using high ink volumes. Our film offers fast drying and consistent results for professional screen printing.

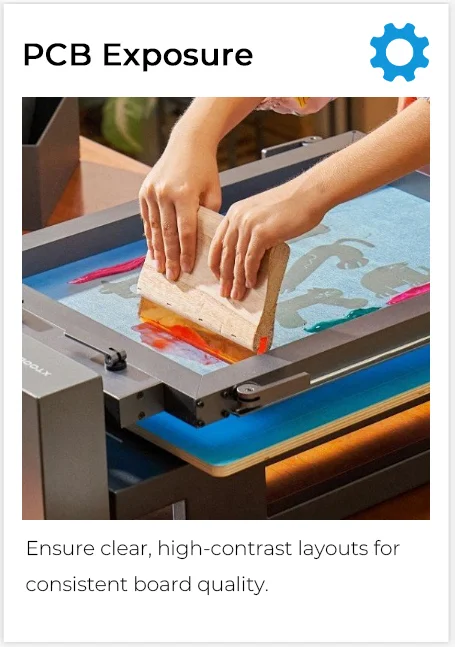

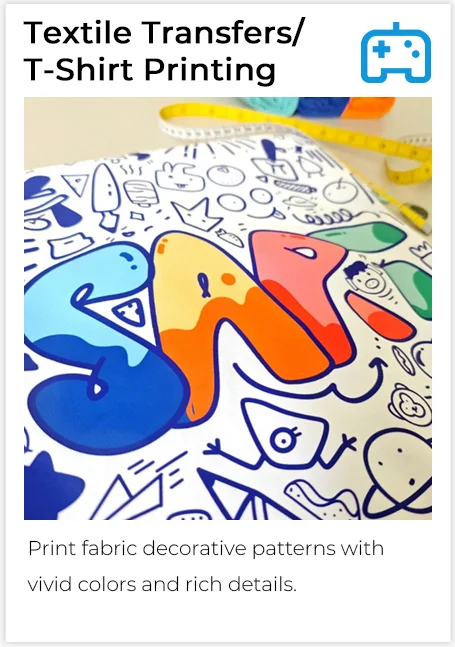

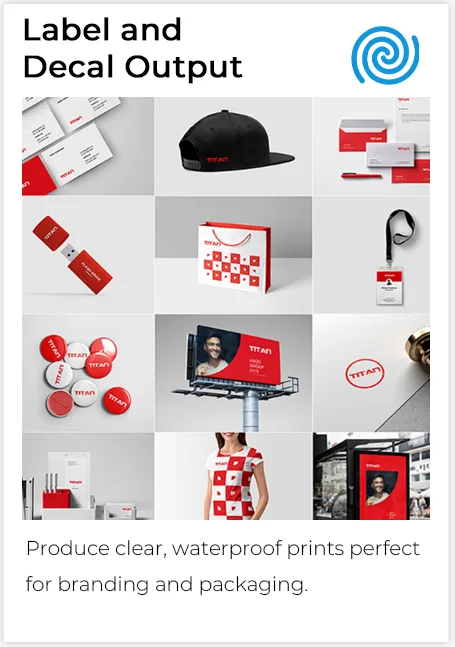

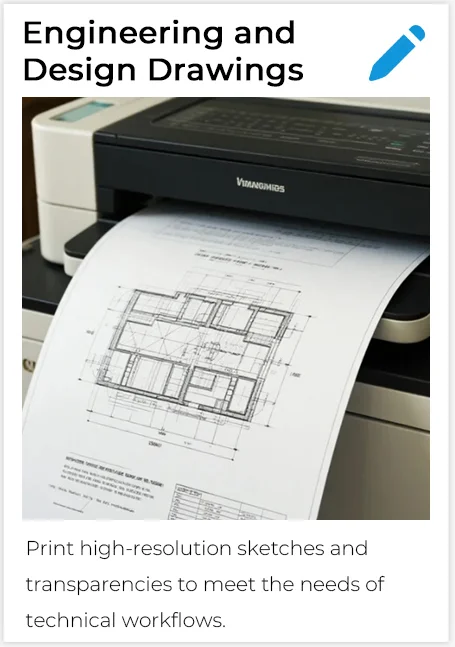

A: Yes. In addition to screen printing, it's suitable for PCB circuit board exposures, UV plate making, engineering transparencies, decal and label printing, and textile transfer positives.

A: Our coating is designed for fast drying. When using dye based inks, it typically dries in 5–8 seconds, while pigment ink dries in 8–12 seconds under normal conditions.

A: Absolutely. We offer OEM options including logo printing, barcode stickers, customized packaging, and carton design. We support MOQ for white-label distribution.

A: Sheets are shrink-wrapped, placed in moisture-resistant bags with desiccants, and packed in reinforced cartons. Rolls are foam-wrapped, bag-sealed, and boxed in export-grade corrugated cases.

A: We follow ISO standards and test each batch of waterproof inkjet film for haze, OD, thickness, curl resistance, coating uniformity, and ink drying. These checks ensure consistent results for screen printing and other film uses.

Our factory passes the ISO9001 quality certification system every year. Our paper is also environmentally friendly and recyclable, and has passed SGS and FSC certifications.

*We respect your confidentiality and all information are protected.

86-025-83313334

86-025-83313334 +86 13770966806

+86 13770966806 86 13770966806

86 13770966806 [email protected]

[email protected]