| Parameter | Specification |

|---|---|

| Product Name | Sticky (Tacky) Sublimation Paper Sheets |

| Available Size | A4 / A3 / Custom Sheet Size |

| Storage | 25°C, 55% humidity |

| Base Weight | 120gsm / 90gsm / 65gsm |

| Surface Type | High-Tack Coating for Elastic or Stretchable Fabrics |

| Adhesion Type | Medium–High Tack (Prevents Ghosting during Heat Transfer) |

| Suitable Fabrics | Polyester, Lycra, Spandex, Elastic Textiles |

| Printing Compatibility | Inkjet Printers (Epson, Sawgrass, Ricoh, Mimaki, Roland) |

| Ink Type | Sublimation Ink |

| Application Temperature | 190–210°C (374–410°F) |

| Transfer Time | 40–60 seconds |

| Application Pressure | Medium |

| Origin | Made in China |

| Target Markets | USA, Canada, UK, South Korea (Personalized Textile & Sportswear Printing Markets) |

| Test Item | Testing Method | Standard Result | Factory Result | Remarks |

|---|---|---|---|---|

| Coating Uniformity (g/m²) | Gravimetric analysis | ±0.5 variation allowed | ±0.2 | Excellent consistency |

| Tack Level Test (N/cm) | ASTM D3330 peel test | 0.25–0.35 | 0.3 | Stable medium tack |

| Ink Absorption Rate (s) | Drop test under 25°C, 60%RH | ≤10 seconds | 5 seconds | Fast absorption |

| Transfer Color Density (ΔE) | Color spectrophotometer | ≤1.0 deviation | 0.65 | Vivid and stable color |

| Surface Flatness (mm) | Optical flatness test | ≤0.2mm | 0.12mm | High planarity |

| Curl Resistance (%) | Controlled humidity chamber | ≤3% | 0.015 | Excellent dimensional stability |

| Wash Fastness (After 30 washes) | ISO 105-C06 standard | Grade 4–5 | Grade 5 | Excellent wash durability |

| Humidity Resistance (24h, 80%RH) | Environmental chamber | No deformation | Passed | Suitable for humid regions |

Our factory passes the ISO9001 quality certification system every year. Our paper is also environmentally friendly and recyclable, and has passed SGS and FSC certifications.

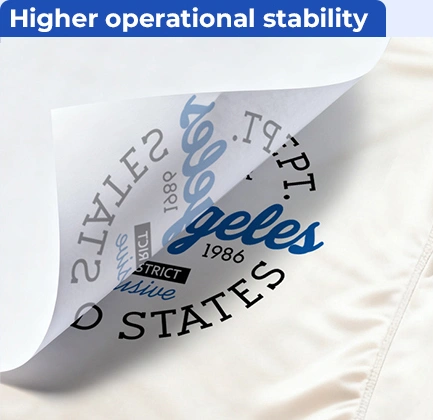

A:Tacky sublimation paper is paper with a light, sticky coating that briefly adheres to the fabric during the heat press process. This prevents shifting and eliminates ghosting or ghosting.

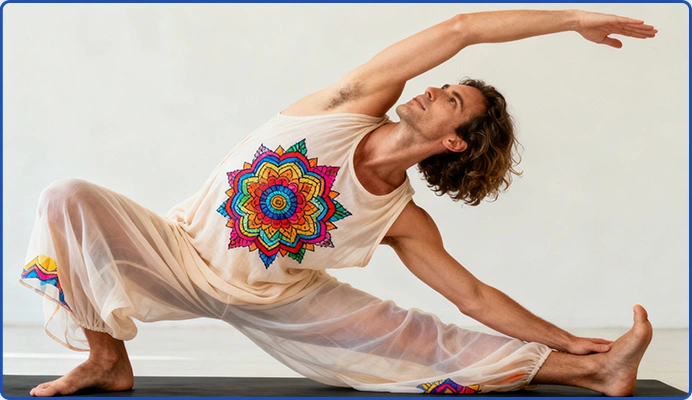

A:Use Tacky sublimation paper when working with stretchy or slippery fabrics.

A:It's particularly suitable for lycra, spandex, polyester blends, stretchy activewear, swimwear, yoga wear, and other fabrics that tend to shift during the heat press process.

A: No. The sticky coating secures the paper in place throughout the transfer process, eliminating the need for heat-resistant tape.

A:No. After cooling, the paper peels off cleanly without leaving any glue or marks, ensuring a smooth, professional finish.

A:No. When used correctly, the transferred image exhibits excellent washability, and the colors remain vibrant and sharp even after multiple washes.

A:We support flexible MOQ based on your business scale—contact us for OEM options.

A:This paper is designed for soft and elastic textiles, not hard substrates.

*We respect your confidentiality and all information are protected.

86-025-83313334

86-025-83313334 +86 13770966806

+86 13770966806 86 13770966806

86 13770966806 [email protected]

[email protected]