UV AB Film for UV Printing – Not DTF Transfer Film

UV A and B Printing Film is a cold transfer labeling solution designed for UV Printer printing only. The image is printed directly onto Film A using UV ink, cured by UV light, laminated with Film B, and then transferred onto the final surface without heat or pressure machines.

Not a DTF transfer film

Not a DTF transfer film

No heat press required

No heat press required

No powder or oven curing

No powder or oven curing

Ideal for hard surfaces and premium decorative labeling.

Ideal for hard surfaces and premium decorative labeling.

A-film + B-film: Complete UV Crystal Label System

The UV crystal label film system consists of an A-film for UV printing and a B-film for cold transfer lamination. The A-film utilizes a UV ink receiving coating that supports high ink load, precise details, and stable curing. The B-film provides a transparent adhesive layer for smooth, bubble-free transfer and leaves no adhesive residue on the final surface.

Film A – UV Printing Film:

Special UV ink-receptive coating

Supports high ink density & sharp details

Stable curing with strong ink fixation

Film B – Cold Transfer / Laminating Film:

High-transparency adhesive layer

Enables clean, bubble-free transfer

No glue residue after peeling

Classification of B-film:

Based on viscosity and application, B-film can be divided into the following two common types:

Standard B-film (medium viscosity):

Suitable for most crystal label transfers, with moderate viscosity, ideal for flat or slightly curved surfaces (such as mobile phone cases, cups, acrylic sheets, etc.).

High-viscosity B-film:

Stronger adhesion, suitable for uneven, rough surfaces or materials requiring higher adhesion (such as leather, wood, frosted surfaces, etc.).

Differences Between UV Film A and Film B

| Characteristics | Film A (Printing Substrate) | Film B (Transfer Film) |

|---|

| Function | Features UV printed patterns and an adhesive layer | Transfers the pattern to the target object |

| Adhesion | Strong adhesion (permanent bond) | Temporary adhesion (removable after transfer) |

| Transparency | Available with white or transparent substrate | Usually highly transparent |

| Removability | Cannot be removed after application | Needs to be peeled off after transfer |

Usage Scenarios and Recommendations:

Transparent B-film: General purpose, suitable for most materials.

High-tack B-film: Solves the problem of insufficient adhesion on curved and rough surfaces.

Custom shapes: Some B-films can be pre-cut for easy transfer of complex patterns.

Precautions:

Ensure that the A-film and B-film are fully pressed together during transfer to avoid pattern residue or breakage. Select a B-film with appropriate tackiness based on the surface material of the target object (e.g., smooth, rough, curved). Low ambient temperatures may reduce the tackiness of the B-film; it is recommended to operate at temperatures above 15°C. Stronger adhesion, suitable for uneven, rough surfaces or materials requiring higher adhesion (such as leather, wood, frosted surfaces, etc.).

Not DTF: UV Printing Film vs DTF Transfer Film

UV A/B Film and DTF Transfer Film differ fundamentally in printing method, transfer process, and application scope. UV A/B Film is based on UV printing with cold transfer, requires no heat press, and is intended for rigid or coated surfaces. DTF Transfer Film uses inkjet printing combined with heat transfer, primarily for textile applications.

| Item | UV A and B Film | DTF Transfer Film |

|---|

| Printing Method | UV Printing | Inkjet Printing |

| Transfer Method | Cold Transfer | Heat Transfer |

| Heat Press Needed | ❌ No | ✅ Yes |

| Target Substrates | Hard surfaces | Fabrics |

| Finish Effect | Glossy / Crystal | Matte / Fabric feel |

Typical Applications of UV Sticker Label Film

The finished label delivers a raised, glossy, crystal-like appearance, significantly enhancing product value.

Brand logos & decals

Glass bottles & cosmetic packaging

Metal nameplates

Acrylic signage

Phone cases & electronics

Promotional gifts & retail displays

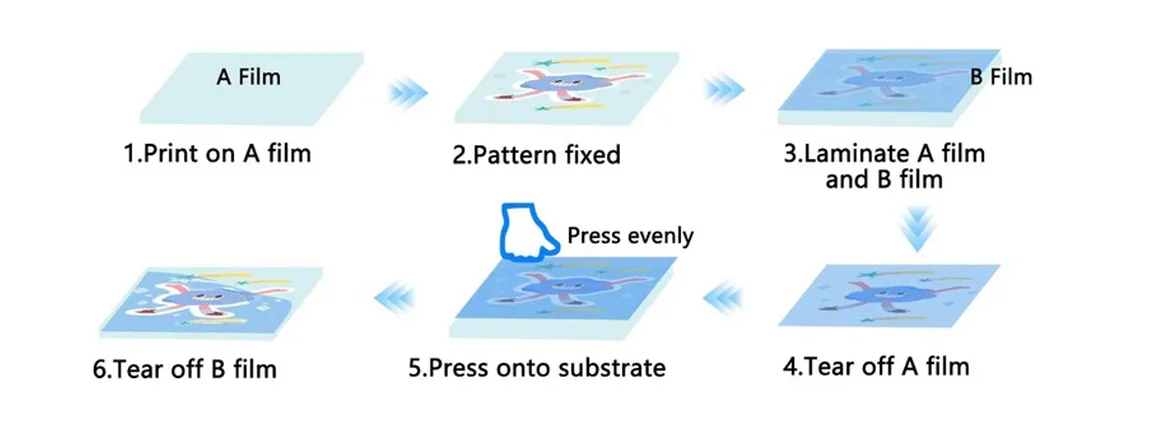

How to Use UV A/B Printing Film

| Grade | Item | Color | Specifications |

|---|

| UV DTF.A | UV DTF Film(A) | White | 600mm*100m;300mm*100m;A4*100;A3*100 |

| UV DTF.A | UV DTF Film(A) | Clear | 600mm*100m;300mm*100m;A4*100;A3*100 |

| UV DTF.B | UV DTF Film(B) | Clear | 600mm*100m;300mm*100m;A3*100 |

Professional Manufacturer of UV Printing Films

With ISO-certified manufacturing facilities and in-house coating and adhesive formulation, we ensure stable batch consistency and reliable quality control across every production run. Backed by years of experience in printing consumables manufacturing, we support OEM & ODM customization and supply UV printing films to distributors, brands, and professional printers across North America and Europe.

Professional Manufacturer of UV Printing Films

ISO-certified manufacturing facilities

In-house coating & adhesive formulation

Stable batch consistency & quality control

OEM & ODM customization supported

Exported to North America & Europe

Strict Quality Inspection form UV Printing Film Factory

Every batch of UV printing film undergoes strict quality inspection before delivery. From coating uniformity and adhesive performance to transfer stability, each production step is carefully monitored to ensure stable quality, consistent performance, and reliable results for professional use.

| Item | Unit | Reference Specification | Test Method / Remark |

|---|

| Appearance | — | Smooth surface, no scratches, no deformation, no wrinkles, no streaks, no coating missing or pinholes | Visual inspection |

| Color | — | Transparent | Visual inspection |

| Working Layer Thickness | μm | 28 ± 2 | Micrometer |

| Peel Strength (25 mm) | gf / 25 mm | 3–5 gf | Tensile tester |

| Peel Strength (75 mm) | gf / 25 mm | 10–15 gf | Tensile tester |

| Width | mm | Customized according to customer requirements, tolerance ±1 | Measuring tape |

| Initial Tack | # | ≥ 3# | Ball tack tester |

| Peel Adhesion Strength | gf / 25 mm | ≥ 1800 gf | Tensile tester |

| Holding Power | 25 × 25 mm | No displacement after more than 200 hours | Holding power tester |

| High-Temperature Holding Power | 25 × 25 mm | No displacement after more than 48 hours | Holding power tester |

| 85°C / 85% RH Test | 72 h | No discoloration, cracking, delamination, adhesive failure, or whitening | Constant temperature & humidity chamber |

| High / Low Temperature Cycling | 72 h | No discoloration, cracking, delamination, adhesive failure, or whitening | Constant temperature & humidity chamber |

Frequently Asked Questions for UV Film

Q:Is this a DTF transfer film?

A:No. This is a UV printing film for cold transfer, not a heat transfer material.

Q:Do I need a heat press machine?

A:No heat press is required.

Q:What printers are compatible?

A:UV flatbed printers and UV roll printers.

Q:What surfaces can it be applied to?

A:Glass, metal, acrylic, plastic, coated wood, and other smooth surfaces.

ISO9001 Certification | FSC Certification

Our factory passes the ISO9001 quality certification system every year. Our paper is also environmentally friendly and recyclable, and has passed SGS and FSC certifications.

Not a DTF transfer film

Not a DTF transfer film No heat press required

No heat press required No powder or oven curing

No powder or oven curing Ideal for hard surfaces and premium decorative labeling.

Ideal for hard surfaces and premium decorative labeling.

86-025-83313334

86-025-83313334 +86 13770966806

+86 13770966806 86 13770966806

86 13770966806 [email protected]

[email protected]